The manufacturing sector, traditionally characterised by its heavy reliance on physical processes and labour, is currently undergoing a significant transformation, ushered in by the digital era.

This digital shift represents a fundamental rethinking of manufacturing operations and strategies.

At the heart of this transformation is the integration of digital technologies into all areas of manufacturing. This shift, often termed ‘Digital Transformation in Manufacturing,’ involves the use of advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), robotics, and cloud computing.

These technologies are revolutionising manufacturing processes, making them more efficient, agile, and customer-focused.

Embracing the Digital Era in Manufacturing: Meeting Market and Consumer Demands

One of the key drivers of this transformation is the need to meet changing market demands and customer expectations.

Today’s consumers seek personalised, high-quality products with shorter lead times, driving manufacturers to turn to digital solutions to meet these needs.

For instance, the use of online seller platforms and B2B apps for retailers have become increasingly prevalent, allowing manufacturers to streamline their supply chains and reach new markets more efficiently.

The ONDC seller app exemplifies this trend, offering manufacturers a platform to expand their market reach and embrace e-commerce effectively. This tool signifies the broader movement towards a digitally empowered manufacturing sector, where traditional processes are augmented by advanced technologies.

Digital transformation in e-commerce is also prompting manufacturers to rethink their business models.

From product development to after-sales service, digital technologies are enabling manufacturers to offer more value to their customers, thereby creating new revenue streams and business opportunities.

The Importance of E-Commerce for Manufacturing Companies: How Crucial is it?

In the rapidly evolving landscape of modern manufacturing, e-commerce for manufacturing companies has emerged as a crucial element for business growth and sustainability.

The integration of e-commerce into manufacturing is no longer just an option but a necessity, driven by the digital transformation in the industry. This shift towards e-commerce for manufacturing companies opens up a myriad of opportunities, fundamentally changing how they operate and compete in the global market.

The benefits of embracing e-commerce in manufacturing are multifaceted.

Firstly, it significantly broadens the market reach, allowing manufacturers to tap into new customer segments and geographic territories with ease. By leveraging online seller platforms, manufacturers can showcase their products to a wider audience, breaking free from the limitations of traditional brick-and-mortar sales channels.

This expansion is about reaching more customers, along with accessing new and diverse marketplaces where demand for their products might be higher.

E-commerce also introduces a higher degree of efficiency and agility in operations. Digital platforms can streamline processes from order taking to fulfilment, reduce overhead costs, and provide real-time data to inform business decisions.

Moreover, the adoption of B2B apps for retailers in the manufacturing sector allows for better collaboration with distributors and suppliers. This enhances the supply chain’s responsiveness and resilience.

Overcoming Market Expansion Hesitancy: What are Companies Thinking?

Despite these advantages, some manufacturing companies exhibit hesitancy in embracing e-commerce, primarily due to uncertainty about the effectiveness and ROI of these platforms.

Concerns about the integration of traditional manufacturing processes with online sales channels and the perceived complexity of managing e-commerce operations are common.

However, platforms like the ONDC seller app are specifically designed to address these concerns. They offer user-friendly interfaces, integration capabilities with existing manufacturing systems, and support for navigating the e-commerce landscape.

These platforms simplify the transition to digital, making it more accessible for manufacturers to start small and gradually scale their e-commerce presence.

Ultimately, for manufacturing companies to remain competitive and relevant in today’s market, adapting to the e-commerce model is imperative. The transition may require an initial investment in time and resources, but the long-term benefits of expanded market access, operational efficiencies, and increased customer reach are undeniable.

E-commerce is not just a trend but a strategic move for future growth and success in the manufacturing sector.

Digital Transformation: A Fundamental Shift from Traditional Processes?

In the manufacturing sector, digital transformation represents a fundamental shift from traditional industrial practices to a more streamlined, technology-driven approach.

Simplifying digital transformation in this context involves understanding its core components and integrating them into existing manufacturing processes. At its essence, it’s about leveraging technology to enhance efficiency, productivity, and agility in manufacturing operations.

The crux of digital transformation for manufacturing companies lies in adopting technologies like IoT, AI, and cloud computing. These technologies enable manufacturers to collect and analyse data in real-time, leading to better decision-making, predictive maintenance, and improved supply chain management.

However, the key to successful digital transformation is also integrating these technologies seamlessly with existing manufacturing systems. This integration enhances processes without disrupting the core manufacturing activities.

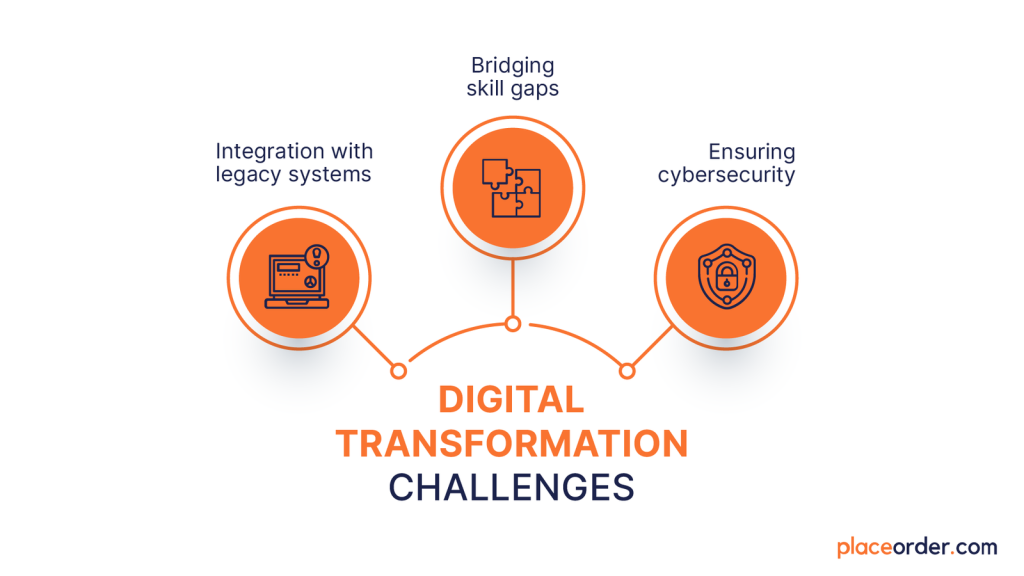

Tackling Digital Transformation Challenges: What are the Obstacles?

The path to digital transformation is often fraught with challenges, particularly for manufacturers entrenched in traditional practices.

One of the primary challenges is the integration of digital technologies with legacy systems. Solutions to this issue include phased technology adoption and using platforms that offer compatibility with a wide range of existing systems.

Another significant challenge is the skills gap. Manufacturers need to invest in training and development to equip their workforce with the necessary digital skills.

Additionally, partnering with tech providers that offer robust support and training can be invaluable in easing the transition.

Manufacturers also face the challenge of ensuring cybersecurity in an increasingly connected environment. Adopting robust cybersecurity measures and protocols is essential to protect sensitive data and operations.

Integrating E-Commerce with Manufacturing: A Strategic Advantage

The integration of e-commerce into the manufacturing sector promises enhanced market reach, operational efficiency, and customer engagement.

But achieving it requires thoughtful strategies and adaptation. Here we’ve listed some points-

Combining Manufacturing Processes with Online Platforms Effectively

The key to effective integration lies in creating a seamless bridge between the physical aspects of manufacturing and the digital realms of e-commerce. This involves a two-pronged approach: digitising internal manufacturing processes and establishing a strong online presence.

Start by implementing digital tools like IoT and AI for real-time monitoring and automation of manufacturing processes. This step enhances the efficiency of production lines and ensures better quality control, making the business more adaptable to the demands of e-commerce.

E-commerce Platform Integration

Next, integrate these digitised processes with an online seller platform. This could involve setting up a B2B e-commerce platform or leveraging existing online marketplaces.

The integration should focus on ensuring that the data flow between the manufacturing systems and the e-commerce platform is seamless, allowing for real-time inventory updates, order processing, and customer feedback.

Also, use data analytics to align manufacturing output with market demand. By analysing e-commerce sales data, manufacturers can anticipate market trends, adjust production schedules, and manage inventory more efficiently.

Navigating the Integration of Manufacturing Systems with Digital Commerce Platforms

Integrating traditional manufacturing systems with modern e-commerce platforms can be challenging, especially when dealing with legacy systems.

Here are some strategies to navigate this transition:

Customised Integration Solutions

Opt for e-commerce solutions that offer customization. This flexibility allows for the integration of unique manufacturing processes and workflows into the e-commerce ecosystem.

Moreover, implement the integration in phases. Start with core functions like inventory management and order processing before expanding to more complex integrations like real-time production scheduling.

Employee Training and Involvement

Equip your workforce with the necessary skills for managing the integrated system. Regular training and involvement in the integration process can ease the transition and improve adaptation.

On that note, collaborating with technology providers who have experience in integrating manufacturing processes with e-commerce platforms can be useful. Their expertise can provide insights into best practices and help avoid common pitfalls.

It is also important to ensure that the integrated system is scalable to accommodate future growth and secure to protect sensitive data and intellectual property.

Utilising Online Seller Platforms for Growth: What are The Key Factors?

In the contemporary manufacturing landscape, embracing online seller platforms is a strategic move toward sustainable growth and market expansion.

These platforms, exemplified by the likes of ONDC, have revolutionised how manufacturers connect with their customers and markets.

The Role of Platforms like ONDC in Expanding Market Reach

ONDC has emerged as a pivotal player in this digital transformation, offering a platform where manufacturers can significantly extend their market reach.

Unlike traditional e-commerce models, ONDC democratises online sales, offering equal opportunities for visibility and market penetration, regardless of the size of the manufacturing business.

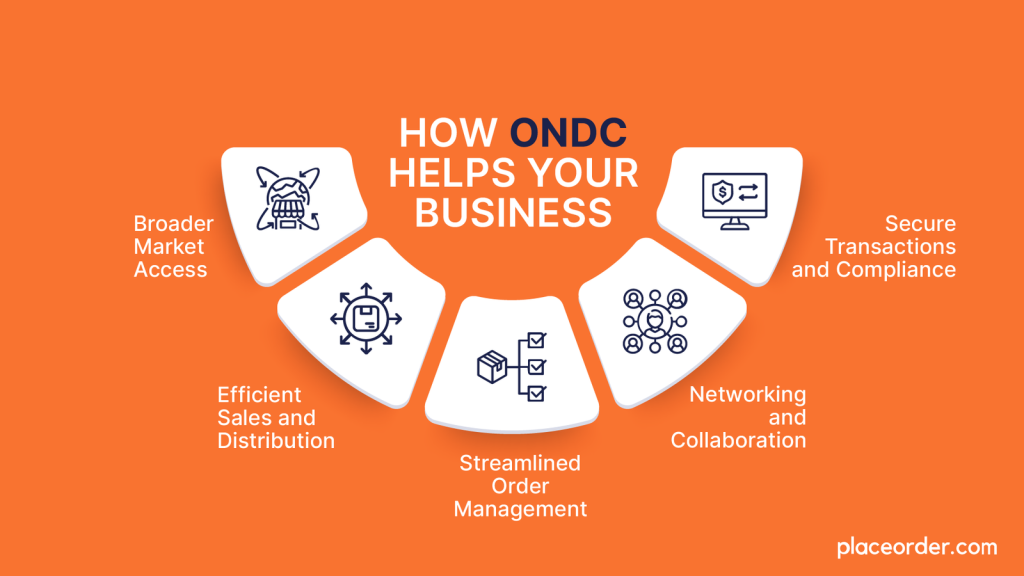

The benefits of using platforms like ONDC for manufacturers are multifaceted:

Broader Market Access

ONDC provides manufacturers with access to a wider customer base, including both national and international markets. This is particularly beneficial for manufacturers looking to diversify their market presence and reduce dependency on a single market or customer segment.

These platforms further offer valuable data and analytics on customer behaviour, preferences, and purchasing patterns. Manufacturers can leverage this data to tailor their product offerings, optimise pricing strategies, and enhance customer engagement.

Increased Efficiency in Sales and Distribution

ONDC integrates various aspects of the sales and distribution process, from listing and marketing products to processing orders and managing logistics. This integration streamlines operations and reduces the complexities associated with managing multiple sales channels.

With tools for targeted marketing and advertising, ONDC even allows manufacturers to effectively reach their desired audience without the hefty costs typically associated with traditional marketing methods.

Streamlined Order Management

Specialised B2B e-commerce applications offer tailored solutions to the unique challenges of the manufacturing sector. These apps provide platforms where manufacturers can not only sell their products but also manage their entire sales cycle and customer relationships.

B2B e-commerce apps often include features for managing orders, inventory, and customer relationships in one place, which simplifies the sales process and enhances customer service.

Collaboration and Networking

B2B e-commerce apps often provide networking opportunities, enabling manufacturers to connect with suppliers, distributors, and even potential business partners. Thus, fostering a collaborative environment that can lead to new business opportunities.

And unlike generic e-commerce platforms, B2B apps allow manufacturers to present their products in a manner that resonates with other businesses. This allows for highlighting technical specifications and bulk pricing options.

Secure Transactions and Compliance

With robust security features and compliance with industry standards, B2B e-commerce apps ensure that transactions are secure, and trade regulations are adhered to, which is crucial in B2B transactions.

Cost-Benefit Analysis of E-Commerce Initiatives

In the manufacturing sector, the decision to invest in e-commerce is often met with questions about the economic viability and the return on investment (ROI) it offers.

A detailed cost-benefit analysis is crucial to understanding and maximising the potential of e-commerce initiatives.

Insight into Budgeting and ROI for E-Commerce in Manufacturing

The economics of integrating e-commerce into manufacturing involves considering both direct and indirect costs and revenues.

Direct costs include the expenses of setting up and maintaining online platforms, digital marketing, and logistics. Indirect costs might encompass training employees and potential downtimes during the digital transition.

On the revenue side, a Forrester Research study indicates that B2B e-commerce transactions are expected to reach $1.8 trillion by 2023, accounting for 17% of all B2B sales in the U.S. alone.

This suggests a significant revenue potential for manufacturers investing in e-commerce.

Manufacturers should also consider long-term ROI, which includes increased market reach, higher efficiency, and enhanced customer engagement. According to a survey by McKinsey & Company, companies that excel in customer experience grow revenues 4% to 8% above their market.

E-commerce platforms provide an avenue to improve customer experience through personalised services and streamlined operations.

Evaluating the Cost-Effectiveness and ROI of E-Commerce Strategies

When balancing the costs and investment in e-commerce, manufacturers must consider both immediate and long-term returns. The initial setup cost for e-commerce platforms can be offset by the increase in sales volume and market share.

Also, e-commerce allows for data-driven decision-making, which can lead to cost savings in areas like inventory management and supply chain optimization.

Moreover, e-commerce initiatives offer scalability. As the business grows, these platforms can adapt and expand without significant additional investment.

This scalability is critical for manufacturers looking to grow their market presence steadily.

Finally, e-commerce platforms can lead to cost savings in traditional sales and marketing. Digital marketing strategies often prove to be more cost-effective than traditional methods, offering higher precision and measurable results.

The Road Ahead for E-Commerce in Manufacturing

As we look toward the future, it’s clear that e-commerce is a transformative force in the manufacturing industry.

The journey of integrating e-commerce into manufacturing has been one of adaptation, innovation, and growth. With the global B2B e-commerce market expected to reach $20.9 trillion by 2027, growing at a compound annual growth rate of 17.5% from 2020 to 2027, the potential for growth in this space is immense.

Manufacturers who embrace e-commerce are positioning themselves to tap into new markets, streamline their operations, and meet the evolving needs of a digital-first customer base.

The role of online platforms like ONDC and specialised B2B e-commerce apps in this evolution cannot be overstated. They are the tools that will drive efficiency, scalability, and connectivity in the new digital manufacturing landscape.

Next Steps for Manufacturing Business Owners

For manufacturing business owners standing at this crossroads, the next step is clear: embrace e-commerce and harness its potential.

It’s time to explore e-commerce strategies that align with your business goals, to invest in digital platforms that will broaden your market reach. And also to adapt your operations to the efficiencies that e-commerce offers.

This journey into e-commerce is about keeping pace with competitors and seizing the opportunity to redefine what your manufacturing business can achieve in the digital era. The future is digital, and for manufacturers, the time to act is now.

The Digital Revolution in Manufacturing is Here!

Step into the future of manufacturing today by embracing e-commerce strategies that propel your business forward.

Don’t let your manufacturing company be left behind in an increasingly digital world. Explore the expansive opportunities provided by platforms like the ONDC seller app, and witness how they can transform your business operations, broaden your market reach, and drive substantial growth.

Act now, harness the power of e-commerce, and position your manufacturing business at the forefront of innovation and success.